Unit 3 Alexandra Business Centre, Alexandra Road, Addlestone, Surrey, KT15 2PQ

London Spray Finishes

Substrate Requirements

The vast majority of substrates can be spray finished.

In order to achieve the highest quality finish with MDF and natural wood substrates, there are some points to take into consideration within the construction stage.

Substrates supplied to us without the below specifications (unless stated within the quotation), will incur an hourly charge to rectify any imperfections. Alternatively, items can be returned to the client to make the necessary corrections themselves.

Please be aware that these are only guidelines, for the purpose of saving time, money, and confusion in the production process.

Substrates

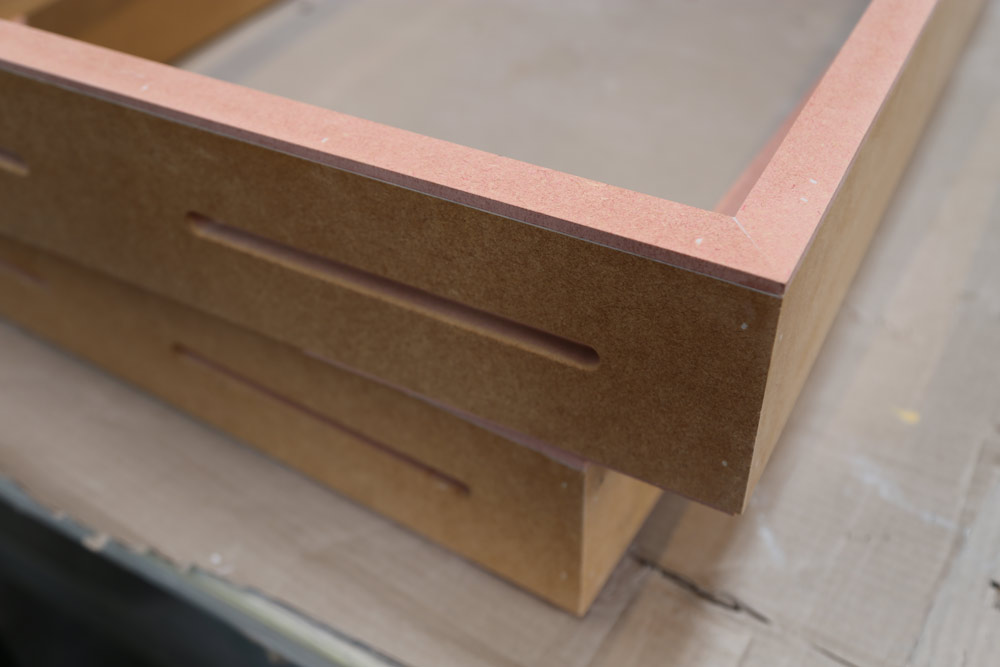

MDF is ideal for joinery construction. The edges require sanding prior with 240 grit sandpaper, to allow full absorption of the material applied.

Flame retardant MDF is suitable for passing fire certificates when required.

Waterproof MDF is recommended for kitchen & bathroom applications.

Plywood is acceptable as a substrate, but requires the application of Polyester primer and further filling on the edges.

Natural timbers also require polyester coating to fill the grain, in order to achieve flat, smooth finishes.

Construction

MDF and timber joinery should be constructed so that the joints are not protruding the surface; this is most visible on mitre joints, particularly on doors that have beaded sections.

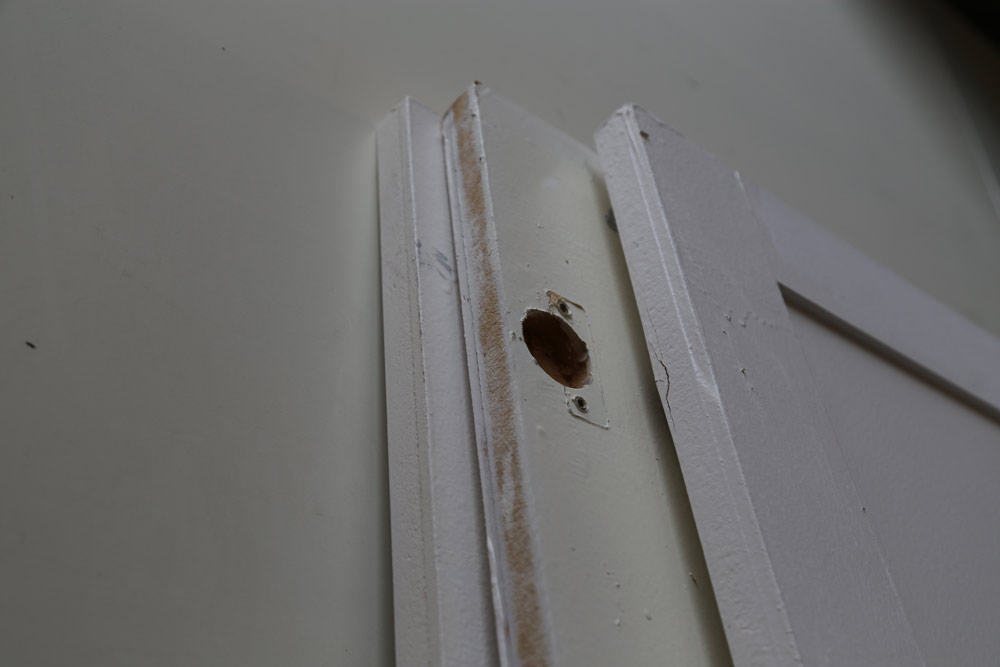

In order to achieve the best finish, drawer fronts, plinths, fascia boards, tops and any other areas that are in direct eyeline, should ideally be removed prior to work commencing. Fragile frames should be braced extensively with corner braces, to ensure that the items are securely fastened, and that movement is non-existent. When filling imperfections, two pack body filler is preferred; we use Upol, Top-stop, Gold and Easy3 filler. Pins, nails, and screws should be counter sunk, filled, and sanded flat, prior to the delivery of items.

Examples

Discuss your project

Get in touch with our team to collaborate or enquire about a project.