Unit 3 Alexandra Business Centre, Alexandra Road, Addlestone, Surrey, KT15 2PQ

Spray Finishing Services

We offer a range of finishes, which can be applied to the vast majority of substrates, both internal and external, to suit a broad spectrum of tastes and preferences.

There are numerous types of substrates which can be spray finished, the most common substrates that our clients work with are: MDF, veneered MDF, solid hardwood timbers, UPVC, plastic, and ferrous and non-ferrous metals, for both interior and exterior finishes.

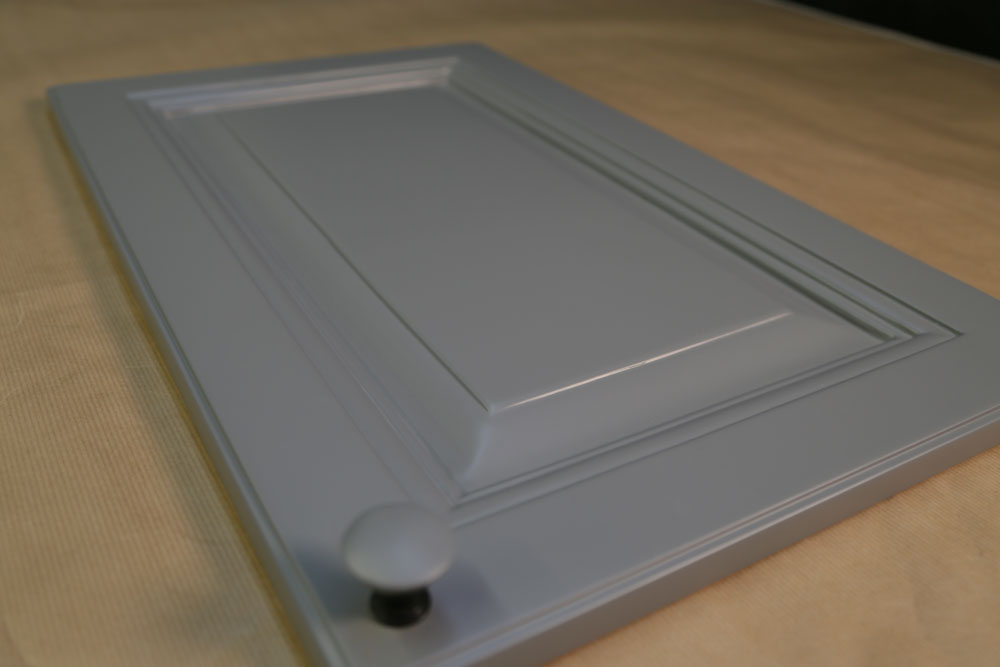

Whether you want to transform an old, cherished piece of furniture to its former glory, or upgrade a factory finished kitchen to a bespoke colour & sheen level, our highly experienced team are on hand to help. We also offer an express delivery service.

Paint Spraying

We provide a high-quality showroom finish to both newly manufactured items and existing items, with sheen levels ranging from 2% dead matt to 97% high-gloss sheen level.

There are various types of spray finishing applications that we use, each application is determined by the following factors, these are: the environment which the product will be subjected to, the purpose of the product, for example, a fire-retardant finish for health & safety regulations and the expected amount of contact with the product i.e., whether this is in an area of high-footfall or high-contact.

We hold extensive paint samples of all the major paint suppliers including: Pantone, Farrow & Ball, Paint & Paper Library, Dulux Professional, Little Greene, Fired Earth and RAL, alternatively we can use laser technology to colour match items or sample pieces supplied to us, which may have been discoloured, or custom made.

The various types of spray finishing paint applications and materials that we use include:

-

Polyurethane

The majority of the paint finishes we apply are Polyurethane, due to its water-resistant and anti-scratch properties.

-

Priming only

We use a polyurethane based primer, which is specifically tailored for clients who require hand-painted, topcoat finishes.

-

Polyester

Specifically made for products which are in high-contact and high-footfall areas, which are likely to be prone to damage.

-

Oil Based

Commonly used for outdoor substrates which endure various weather conditions, such as bespoke sache windows and outside furniture.

-

Heat & Fire retardants

Fire retardant coatings, which are required for Class 0, Class 1 & Class B are available; these are usually used in public areas, such as museums and hotels.

-

Metallic

This is purely for decorative purposes. This can be used as an alternative to liquid metal finishing, where clients can still achieve a visually impressive finish, which imitates precious metals.

-

Pearlescent

This is purely for decorative purposes. This is used to create pearlescent effects, such as that of mother-of-pearl, with a pearly sheen or soft glow.

Laquer Finishing

We offer a range of lacquer finishes, which range from 2% dead matt, which gives a natural un-lacquered looking finish, to 97% high-gloss, which gives a mirror-like finish. The primary substrate which we work with is wood, however we also work with various substrate types.

The types of lacquers which we use are dependant on factors such as: the environment which the product will be subjected to, for example, excessive moisture in a bathroom, the purpose of the product, for example, to adhere to building regulations where wooden substrates are to be lacquered with a fire-retardant material, and the expected amount of contact with the product i.e., whether this is in an area of high-footfall or high-contact, for example, a bar countertop.

The most common lacquer, which is applied to timber substrates, for internal applications is PU Acrylic, this is due to its non-yellowing and UV resistant properties. Other lacquers which we use are:

-

Water-based

This is an environmentally friendly application, suited for on-site spray applications, where substrates or fixed installations cannot be removed.

-

Polyurethane

The majority of factory finished substrates are sprayed using Polyurethane lacquer, due to its smooth, water-resistant, and anti-scratch properties.

-

Acrylic Lacquers

Predominantly used for applications to external metal substrates, which are exposed to various weather conditions.

-

Acid Catalyst Lacquers

Predominantly used for its high-wear and high-usage properties. Suitable for high-contact areas such as lifts or lobby doors & desks.

-

Oil-based

Commonly used for outdoor substrates which endure various weather conditions, such as bespoke sache windows and outside furniture.

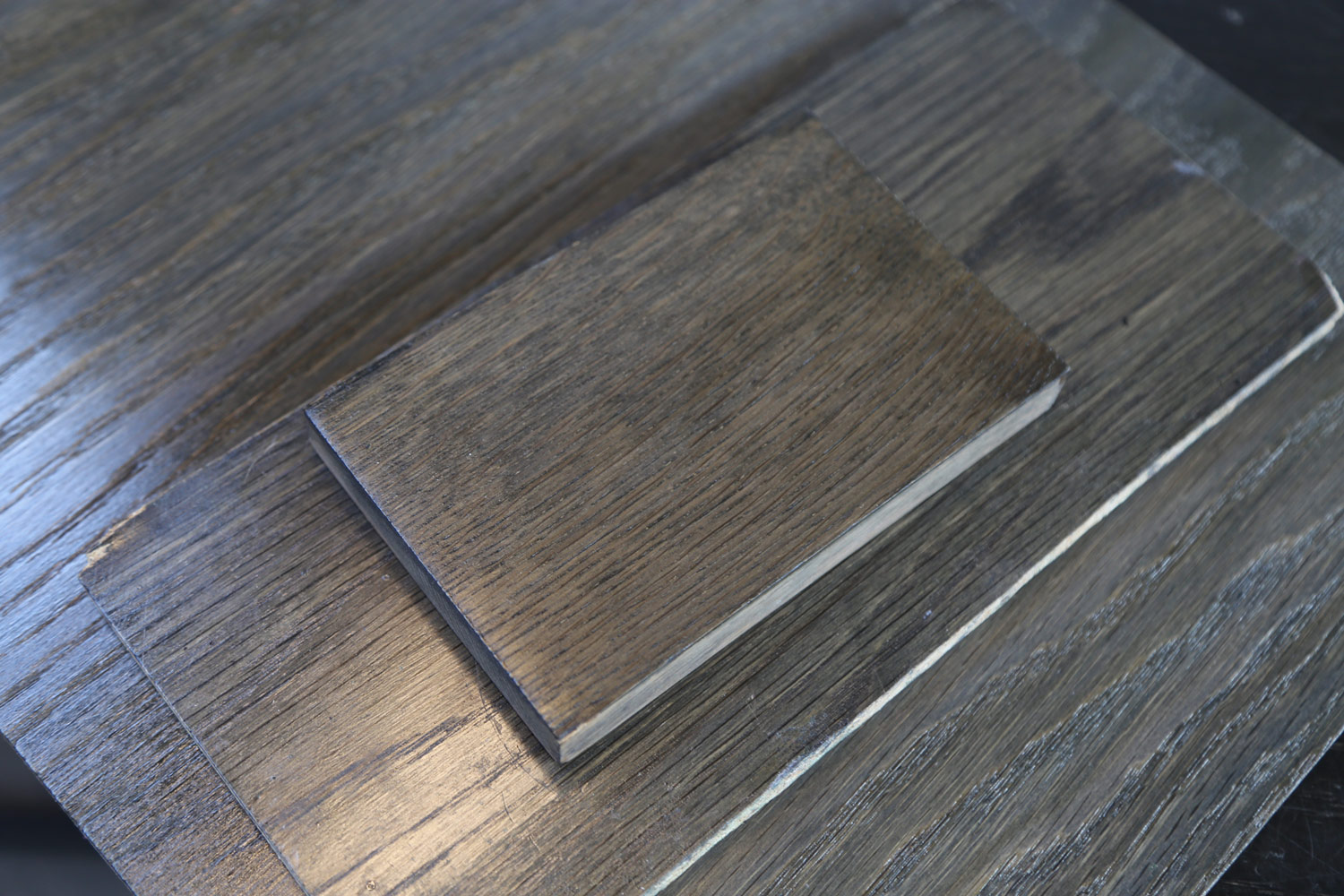

Bespoke colour matched lacquer finishes

Due to extensive French Polishing experience, we can match the exact depth of finishes, to show multiple hues, sheen level and colour.

Bespoke lacquer finishes are colour matched to replicate existing finishes or to match samples which are provided to us. Bespoke colour matching services are used for various purposes, such as:

To match new joinery installations with existing wooden fixtures in order to achieve the same effect

To match two different types of wood

To match multiple types of the same wood from different batches or sources, for example, matching European Straight Grained Oak with American Oak

To match solid wood substrates to laminates or engineered surfaces.

Repairs & Restoration

London Spray Finishes technicians are trained in repairing various substrates with a range of finishes and styles which can be applied to both interior and exterior substrates.

Repairs range from restoration to modernisation, such as restoring old items of furniture with new hinges and handles, to bringing new character to items of furniture, by applying distressing techniques to achieve an antique look.

London Spray Finishes are experiences in repairing a range of substrates from: MDF, veneered MDF, solid hardwood timbers, UPVC, plastic, and ferrous and non-ferrous metals.

On-site Hard Surface Repairs

London Spray Finishes specialise in the on-site repairs of damaged items, such as kitchen surfaces, worktops, and other hard surfaces which are prone to damage caused by impact.

Types of damage that we encounter include chips, dents, burns, scorch marks, scratches or blown MDF from excessive moisture.

We ensure that the repair finish matches that of the existing surface, by replicating the colour and sheen level, which in turn saves you time and money, when compared to the time and cost involved in sourcing and installing replacement products.

On-Site Spraying

On-site spraying is a great way to rebrand, restore or refresh tired looking surfaces without the outlay and disruption of replacing existing installations.

London Spray Finishes work within the domestic and commercial markets, transforming a variety of materials and surfaces, whether old or new, into seamless high-quality finishes. Our projects range from carrying out spraying to shop fronts in need of a make-over, to rejuvenating existing kitchen units or fitted wardrobes. We offer a variety of colours and coatings from all major paint suppliers, as well as a bespoke colour matching service.

Health & safety is our top priority; therefore, we use environmentally friendly, low-odour, water-based materials (unless specified otherwise) to ensure for a safe working environment for both our technicians and the public. This method also ensures a cleaner process, with minimal overspray and minimal disruption to the business or the homeowner.

Discuss your project

Get in touch with our team to collaborate or enquire about a project.